Cardboard engineering is about more than just cutting board to size

It’s about solving real-world packaging, display, and promotional problems with the right shape, the right material, and the right finish.

At Limehouse Board Mills, we’ve been crafting custom cardboard structures since 1860. Whether it’s a rigid point-of-sale unit, a fold-flat promotional stand, or a bespoke packaging insert, our team engineers each product from the sheet up.

If it’s made of cardboard, we can build it.

Designed for Use — Not Just Display

Whether your product is going into chilled storage, onto a retail shelf, or across an exhibition stand, we engineer it for the environment it’ll face. Every structure is prototyped, pressure-tested, and refined before it goes to full run. It’s built to do the job, not just tick the brief.

Moisture resistance

Grease barrier requirements

Weight and load-bearing properties

Transport footprint

Flat-pack assembly

Ease of branding across different versions

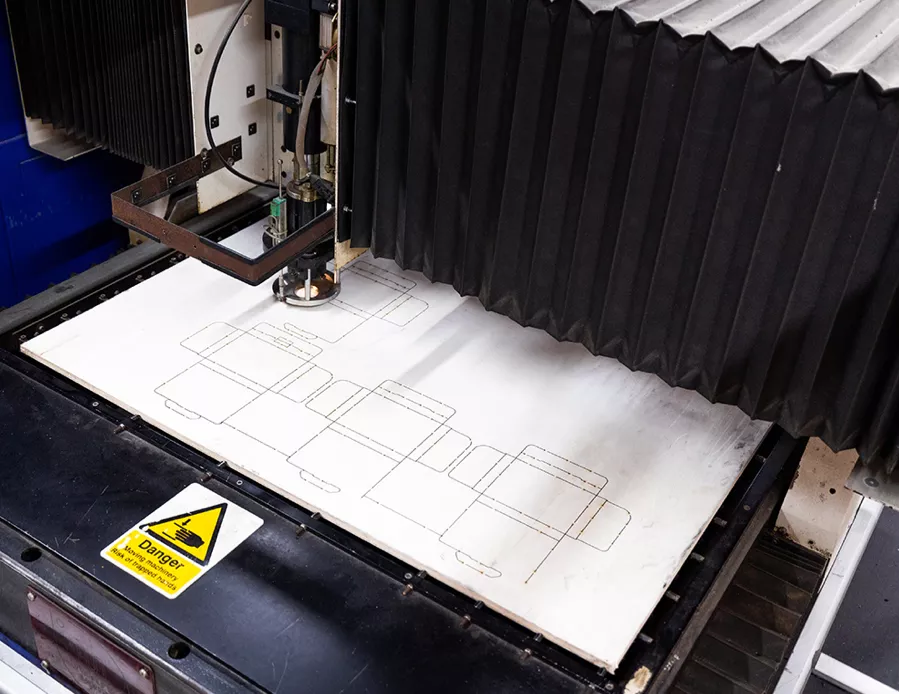

From CAD to Cutting Table

We don’t do generic. Every job starts with your requirements: shape, strength, print, assembly style, and environmental priorities. Then we build from there.

Our cardboard engineering services cover:

- Retail POS units (folding and rigid)

- Exhibition displays and pop-ups

- Window displays and signage

- Custom cartons and promotional packaging

- Protective packaging inserts and liners

- Bespoke fruit punnets, bakery boards, and patisserie packaging

- Diecut, glued, moulded, or guillotined sheet formats

We combine design service, CAD prototyping, and in-house manufacturing. That means speed, flexibility, and complete control over quality, finish, and format.

Real Engineering, Real Outcomes

Soap Pack Interleaves That Don’t Stick

A soap exporter needed sheets between bars, and the old solution allowed grease to seep through, causing the bars to stick and break. We developed a thin, white, grease-resistant board with anti-stick surfaces on both sides. It’s still in use today with no grease bleed, no waste.

Recyclable Handles That Replace Plastic

A retail potato supplier wanted to replace stitched-in plastic handles on paper sacks. We trialled multiple builds and engineered a strong cardboard handle that wouldn’t tear at the join. Fully recyclable. No tooling changes needed.

Diecut Reel Protection That Cuts Handling Time

One customer used plastic film and double-sided tape to protect product reels during crane lifting. We replaced it with a self-adhesive, diecut board panel, rigid enough to prevent scrape damage and quick to apply. Saved time, cut materials, and looked smarter.

Rigid Pallet Sheets That Prevent Damage

A powder chemical manufacturer was losing product in transit due to pallet compression and rubbing. We engineered thick, rigid cardboard sheets to act as interlayers, reducing movement and preventing bag rupture during export.

Luxury Bakery Boards On Tight Turnaround

A bakery launching a patisserie range needed premium packaging boards to spec, but off-the-shelf options weren’t cutting it. We built a solution to meet colour, shape, and structural needs, then delivered the full run in time for launch.

Moisture-Proof Fruit Punnets

Original diecut handles on our cardboard punnets were struggling in humid environments. We upgraded to a stronger, water-resistant board and reshaped the handle for faster assembly. Better performance, fewer returns.

Designed to Be Assembled, Shipped, and Used — Not Just Admired

Our builds work for real-world use:

- Flat-pack formats that ship easily

- Quick assembly with no tools or extras needed

- Strong enough to carry weight, light enough to move

- Folding and rigid variants depending on the application

- Modular designs for retail rollouts or multi-use events

Your cardboard structure isn’t just part of a display; it is the display, the protector, the first impression. We make sure it delivers.

Sustainability Isn’t an Afterthought

Sustainability is built into every part of our process, not tacked on at the end. We use:

- Recyclable materials sourced responsibly

- Lightweight boards to reduce shipping carbon

- Greaseproof and moisture barrier coatings that avoid plastics

- Sheet formats that minimise waste

- Products designed to be recycled at the end of life

If your team is targeting low-waste, plastic-free, or carbon-reduced options, we’re ready to help you spec the right structure.

Perfect for:

- Retailers and visual merchandisers: Custom cardboard displays, window signage, and POS stands

- Marketing teams: Promotional cartons, pop-up displays, and branded inserts

- Product manufacturers: Rigid packaging structures and moisture-resistant solutions

- Exhibition designers: 3D modular displays, free-standing signage, and event build-outs

- Sustainability leads: Plastic-free, environmentally friendly materials with low-impact specs

Why Limehouse Board Mills?

From bespoke prototyping to large-scale manufacturing, our team works with your brand, application, and supply chain to get the structure right and delivered on time.

Over 160 years of experience

All board processing under one roof

Next-day delivery available

Flexible, low MOQ runs

Let’s Get Your Project Moving

You’ve got the idea. We’ll engineer the board that makes it real.

Get in touch to talk about your:

- Next POS display

- Window signage

- Custom folding carton

- Exhibition structure

- Or anything else made from card

Bulk Ordering

For businesses large and small.

Eco-Aware Products

Recyclable, compostable, and food-safe.

Built to perform

Packaging that holds up and looks right.

Our commitment to sustainable packaging

Sustainable, compliant & customised cardboard Solutions

We believe packaging should protect more than just products — it should protect the planet too. That’s why we use responsibly sourced materials, meet strict industry standards, and manufacture recyclable boxes tailored to your exact needs.

- We manufacture with cardboard that is made from a minimum of 70% recycled materials.

- We are FSC certified and source our raw materials from sustainable forests.

- We conform to major retailer and industry requirements.

- We cater to all primary pack formats and packing processes.

- Our boxes are manufactured to your needs.

- Our boxes are 100% recyclable.